Supplier Managed Programs

At CORECHIPS, quality assurance begins with our commitment to source quality products from electronics suppliers around the world.

Trusted & Verified

Through our supplier managed program, we carefully research and prequalify our suppliers to ensure product is procured from safe and reputable sources. In addition, we thoroughly prescreen all prospective vendors based on a rigorous set of product quality, dependability, and service standards.

Once a supplier is added to the CORECHIPS “approved supplier list,”we continually monitor and grade each supplier based upon a set criteria, including product quality history, performance and service fulfillment –identifying any potential problems or concerns well in advance, before product ever reaches our customers.

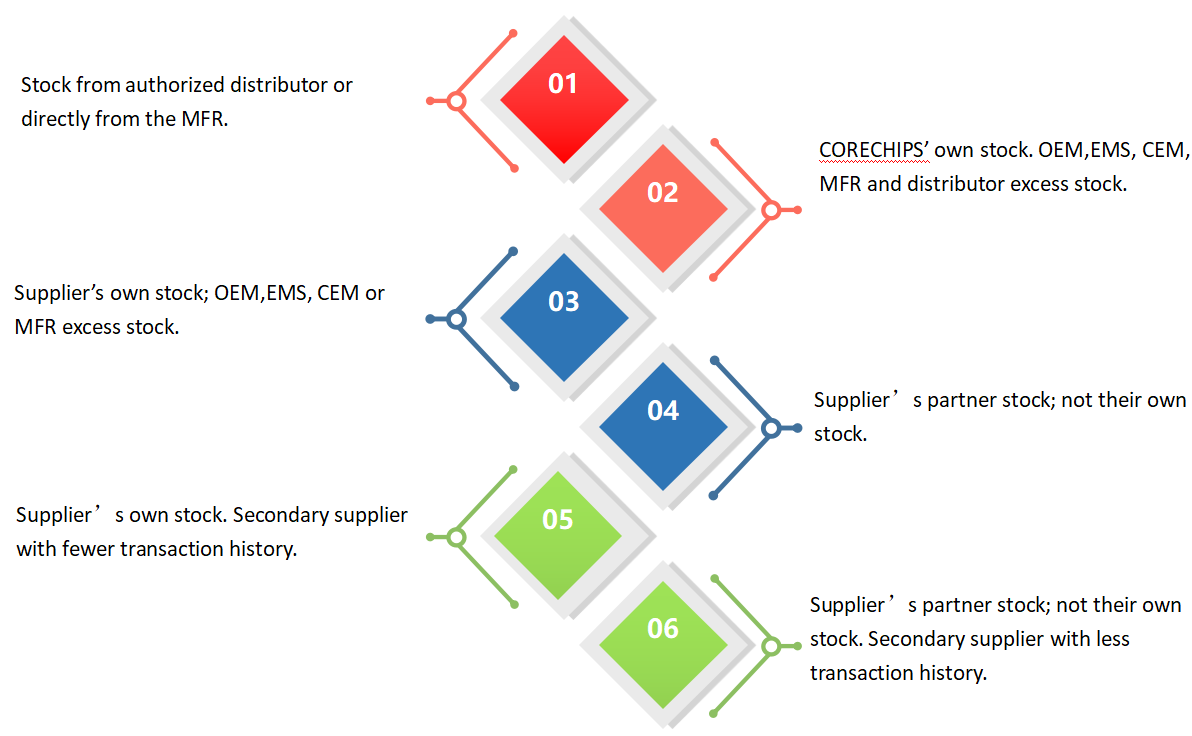

Supplier Rank(Supplier Reliability Level)

Quality Inspection Process

Rigid quality control systems ensure that CORECHIPS delivers only the highest quality products to our customer. CORECHIPS uses a comprehensive due diligence inspection program for all products prior to delivery, incoming inspection methods are based upon customer specified requirements and CORECHIPS’ quality standards. CORECHIPS’ in-house & third-party inspection capabilities include:

Level 1: Visual Inspection

Visual inspection and authenticity verification is conducted on all incoming materials by CORECHIPS inspectors. Visual inspection review includes:

· 1 Manufacturer P/N, quantity, and date code verification

· 2 Body marking inspection (faded marking, broken text, double print, ink stamps, etc.)

· 3 Physical conditions inspection (lead bend, scratches, chipped edges, etc.)

· 4 Taping condition inspection (dented packet, missing parts, etc.)

· 5 Verify moisture barrier protection verification (vacuum sealed, humidity indicator with specification)

· 6 Original factory sealed components vs. non-factory seal

· 7 Any visual irregularities

Level 2: Engineering Review

Materials identified as questionable during the visual inspection process are reevaluated by CORECHIPS staff engineers. Product sampling plans are also employed to ensure product consistency. Engineering review includes:

Review of level 1 findings

· 1 Counterfeit databases referenced and updated

· 2 Label verification (bar code and label review)

· 3 Manufacturer logo and date log verification

· 4 ERAI counterfeit alert program

Level 3: Testing

Product testing is completed to ensure that any questionable materials meet manufacturers' specifications. Product samples are also periodically tested to ensure product consistency and testing. Testing includes:

· 1 Decapsulation test

· 2 Solderability test

· 3 Surface contamination analysis

Electronic Components Distribution - Testing

– To ensure the broadest, deepest and most dependable network of quality electronic components, CORECHIPS has developed a global network of third-party testing laboratories to provide expert product testing during quality assurance evaluations.

– Testing of products is completed by certified partner laboratories that work to ensure that materials identified as questionable meet manufacturers’ specifications and requirements. This global network provides CORECHIPS access to technical know-how and state-of-the-art technology, adding these core competencies to our distribution service offerings.

– In addition, electronic component product samples are randomly selected and tested periodically to ensure product consistency and vendor quality and confirm internal quality controls.

– Testing conducted includes:

– Decapsulation

– Solderability

– X-ray examination

– Contamination analysis

– DC & AC functionality

– Calibration and capacitance measurement

– Electrical

Customer’s Satisfaction

CORECHIPS runs customer surveys with our customers, suppliers and vendors on a regular basis to check our performances; this measure allows us to gather timely and accurate information on our performance, and to make corrections at multiple levels to provide complete customer satisfaction.

· Complete Visual inspection by Corechips’ inspectors

· Chemical De-capsulation, with microscopic die inspection.

· X-Ray Fluorescence Spectroscopy (XRF) testing.

· Data sheet verification.

· Pb-free / RoHS testing

· Solderability testing.

· Reliability testing

· Authenticity Inspection & Verification (AIV)

· Electrical testing / Direct Current Characteristics Test (DCCT)

· Programming

· Functional test

· Failure analyst